Guild Associates' background in gas processing dates back to 2001, when Guild Associates was chosen by Englehard (now BASF) to commercialize the Molecular GateTM technology. Guild has biogas plants in operation at landfills, wastewater treatment plants, lagoon digesters, and other facilities where the biogas is purified to either pipeline or LNG specifications. Our portfolio of equipment includes:

- Feed Compression

- Pressure Swing Adsorption (PSA)

- Temperature Swing Adsorption (TSA)

- Membranes

- Vacuum Compression

- Product Compression

- Thermal Oxidizers and Flares

Interactive Worldwide Locations Map

Below is a map highlighting our locations worldwide. Pan in or out of the map using common Google Maps controls to discover locations using Guild Associates equipment. The carousel below the map also shows the locations and a brief summary of the specifics of the location. Where our customer has agreed, photos and/or contact information is supplied. At these locations, you are welcome to contact these individuals directly concerning Guild Associates' equipment performance.

We have standard system offerings or can custom build a package to meet individual customer needs. Guild Associates' longest running plant has been in operation since 2004. Tours of operating commercial units can be arranged upon request. Below lists the summary of our capabilities in Gas Processing:

- Biogas plant locations in USA, Canada, United Kingdom, Brazil and Philippines

- Feed Flows: 75 to 8,000 SCFM

- Contaminants removed

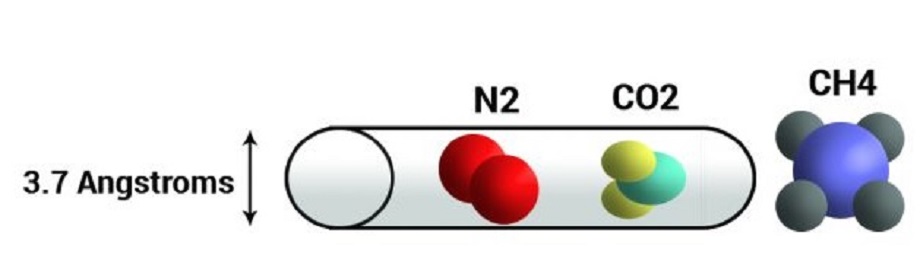

- Bulk rejection of CO2 and N2

- Rejection of trace components including:

- H2S, H2O, O2, VOCs, siloxanes, heavy hydrocarbons (C6+), and Ammonia (NH3)

- Carcinogenic and Non-Carcinogenic Constituents identified in "Biomethane Quality Specifications" of Southern California Gas Company Rule No. 30

- Health Protective Consituents - Carcinogenic and Non-Carcinogenic listed in Table 1 of Pacific Gas and Electric Company Gas Rule No. 21

- Product Compression

- Pressure up to 1,400 PSIG for high-pressure interstate pipeline

- CNG up to 4,500 PSIG with both slow fill and direct fill

Guild Associates has a solution for you. Contact us to learn more.