Biogas from digesters (waste water treatment plants and other digesters) typically have a methane (CH4) content of about 50-60% with the remaining gas being mostly carbon dioxide (CO2) and saturated moisture. Hydrogen sulfide (H2S), Volatile Organic Chemicals (VOC) and siloxanes generally amount to less than 0.5% of the biogas.

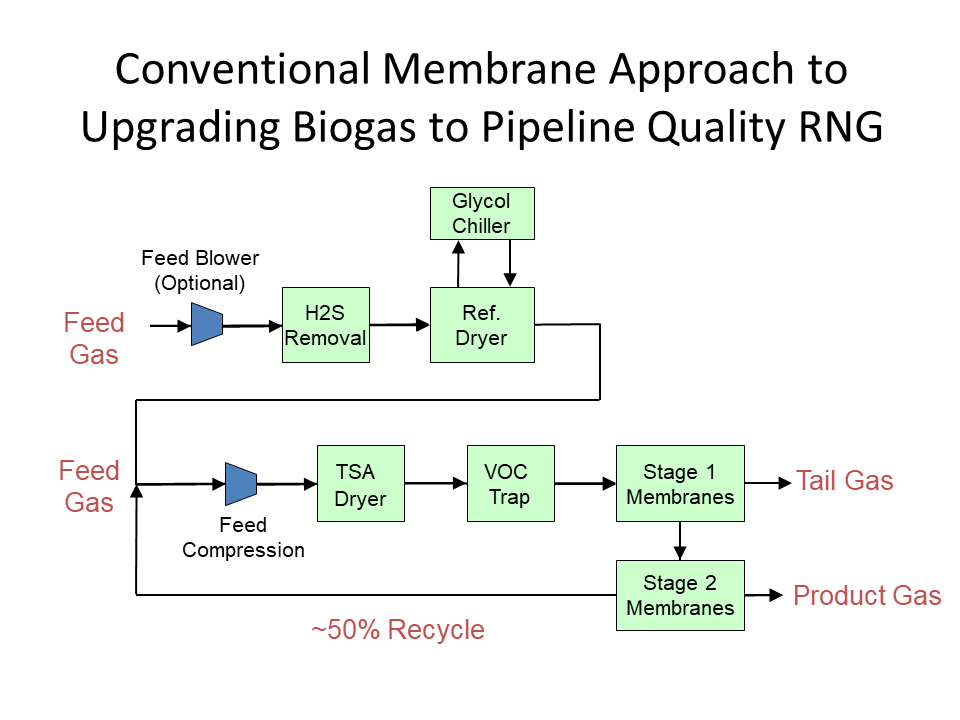

The common industry approach to upgrading biogas consists of using the following process flow:

- Flow into H2S removal skid using a non-regenerable fixed bed media which is replaced on a regular basis (usually 3-4 months)

- From the H2S removal skid, flow into a Refrigerated Dryer skid using a cooling process to remove the bulk of the water

- Compress the resulting gas to about 200 PSIG

Feed the compressed gas into a Temperature Swing Adsorption (TSA) dryer system to remove the water down to pipeline standards - Using a VOC Trap, condense the Volatile Organic Compounds out of the flow to protect the downstream membranes

- If siloxanes are present in the feed gas, the gas flows to a non-regenerable carbon-based or alumina-based adsorbent bed vessel to remove siloxanes, which is also regularly replaced

- Multiple stages of membranes and associated compression to remove the CO2

The Membrane system is consequently a complicated system, as the owner/operator needs to understand and maintain multiple technologies. In the simplified process flow diagram, click or hover over ![]() to display comments.

to display comments.

Feed Gas separately treated for H2S and siloxanes using disposable media, followed by bulk H2O removal with refrigeration system.

Secondary drying and removal of VOCs with disposable media.

Feed compression to 200 PSIG, with up to 50% of the full flow recycled.

Typically 50% of the overall feed flow is recycled back to the feed compression.

Guild Associates has a solution for you. Contact us to learn more.

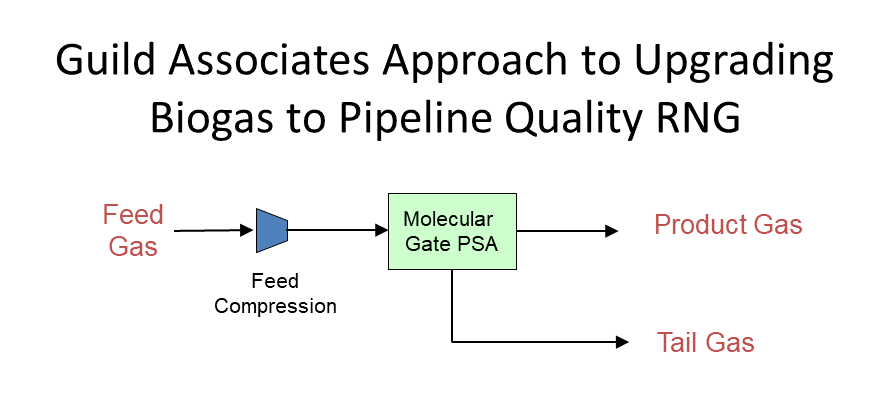

The Guild Associates' Approach to Biogas Upgrading

The video loop shows the simplicity of the Guild Associates' approach to biogas upgrading. When potential customers visit a Molecular GateTM plant, a frequent question is "Where is the rest of the plant?"! WIth no separate equipment containing refrigeration systems and disposable media, the Guild Associates PSA is an simple system to own and operate. And the Molecular Gate media is fully regenerated, expected to last the life of the equipment!

The Guild Associates approach is to use the Molecular Gate advantage in a single step process. The process flow is simple:

- Compress the gas to 100 psig

- Remove the bulk of the moisture using a cooling process, reheating the resulting gas with waste heat from the compressor

- Remove moisture, CO2, siloxanes, H2S and VOCs in a Molecular Gate Pressure Swing Adsorption system

- Deliver the resulting product gas to the local grid at 90 psig.

Hover or click on ![]() in the process flow diagram to display comments.

in the process flow diagram to display comments.

Feed Gas is compressed to 100 psig, bulk water is removed through air-fin cooler and reheated with waste heat of compressor.

In a single-step process, CO2, H2S, H2O, siloxanes and VOCs are removed and sent to tail gas for combustion.

Product gas is delivered to pipeline or compression at 90 psig.

Tail gas is sent to flare or TOX for combustion.

This simple-to-operate technology has been installed at waste water treatment plants and commercial digesters such as hog farms and rendering plants. The technology offers the benefits of:

- Single step removal of impurities

- All media is regenerated – no need for replacement

- H2S completely removed from any level up to 11,000 PPM

- Siloxanes removed to non-detect levels

- Dehydration to CNG requirements without a separate dryer required

- No chillers required

- Dry system operation, with no waste product other than condensed water from compression

Operation and maintenance is much simpler:

- Automatic start-up and shutdown at a push of a button

- Automatic product purity control without operator attention

This is Biogas Upgrading Made Easy! Contact Guild Associates for an evaluation of your site for the Molecular Gate advantage!

Frequently Asked Questions About Biogas Upgrading with Molecular Gate

The adsorbed contaminants are removed from the Molecular Gate adsorbent through the vacuum compressors. The resulting gas from this media regeneration is a low-BTU gas that can either be used as a local fuel (i.e. power generation) or combusted with a flare or thermal oxidizer. Guild Associates can also supply the flare or thermal oxidizer as part of a complete gas processing system.

With no pre-treatment, customers have reported peaks of 11,000 PPM in the feed gas without exceeding pipeline standards in the product gas. Should your feed mixture change over time to include feed material rich in H2S content, there will be no need to invest in larger capacity systems.

The media is fully regenerated and the expectation is that is the media would not require replacement during the plant's operational life. The longest-running systems have exceeded 14 years of life without replacement.