What is Molecular Gate™?

Pressure Swing Adsorption processes have been commercialized for over 60 years. So what makes Molecular Gate unique for PSA processes? The key is the patented Molecular Gate adsorbent. Originally developed by Engelhard (now a part of BASF), Guild Associates is the sole licensee of the technology.

Pressure Swing Adsorption

Pressure Swing Adsorption is a chemical separation process in which a mixture of gases is passed through a bed of adsorbent media at high pressure. Under high pressure, the specific gasses will be selectively adsorbed on to the surface and pores of the adsorbent media. The gasses are removed from the media by “swinging” the media to low pressure, hence the moniker “Pressure Swing Adsorption”. Commercialized systems generally use multiple adsorbent vessels so that one is always in the adsorption mode, while other vessels are regenerated, thus enabling continuous streams of separated gasses.

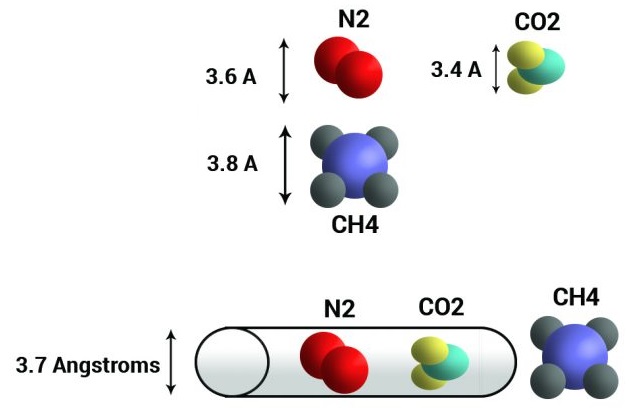

Molecular Gate adsorbent is unique in that the pore size is tightly controlled during the manufacturing of the adsorbent, and thus is customized to most preferentially adsorb a specifically sized target molecule. In the diagram below, note that the size of the pore in the adsorbent is controlled to 3.7 Angstroms. Smaller molecules, such as carbon dioxide (CO2) and nitrogen (N2) are able to fit into the pores and be strongly adsorbed, while the methane (CH4) molecule is too large to fit in the pore. The result is a reliable separation of methane from CO2 and N2.

The Molecular Gate Advantage:

PSA systems with Molecular Gate adsorbent offer advantages over conventional adsorbents for upgrading methane gas streams.

- The methane passes through the adsorbent bed rather than being adsorbed, thus the product gas stream is delivered at high pressure. For applications that are injecting the product gas into gas distribution networks, frequently the additional expense of product compression can be avoided.

- The Molecular Gate adsorbent will preferentially adsorb CO2 over N2. Thus, if a N2 rich feed stream contains a small amount of CO2, the CO2 will be removed to a very low level (typically to <0.005%). Thus, more N2 can be passed through to the product stream without exceeding the product gas specification for inerts, allowing more product flow in a smaller system.

- Molecular Gate adsorbent does not normally degrade in operation and therefore can last the life of the equipment. This reduces maintenance costs and contributes to higher equipment uptime. Molecular Gate adsorbent has exceeded 14 years of life at multiple locations.

Frequently Asked Questions About Molecular Gate Technology

No. Molecular Gate media does not degrade over time and will last the life of the equipment. The longest running equipment has surpassed 14 years without degradation or need of replacement.

Guild Associates' simplified designs and years of field operational experience result in a reliable and maintainable system. A summary of the daily / monthly / annual maintenance is listed below:

Daily

- Visual inspection of fans, heat exchangers, and compressors for leaks or debris that could cause obstructions

- Verification of pressure gauge readings, oil levels, and equipment sounds compared to baseline values

Monthly

- Inspection of condensate knockout pots, lubrication of motor and shaft bearings, and compressor oil sample analysis

Annually

- Oil and filter replacement, compressor alignment, instrumentation calibration, and belt tensioning and alignment

Contact Guild Associates for more details.

No pre-treatment is required. Contact Guild Associates for more information.

Do you have a project in mind?

Download our CUSTOMER QUESTIONNAIRE and send the completed form to Guild Associates. If you have questions or want to discuss your specific application click here to request more information.