Guild Associates, Inc. continues to enhance its reputation as a leader in the field of catalytic materials for decontamination, chemical defense and demilitarization applications. Recent advances by Guild Associates’ technical team have included the development of oxidative catalysts for chemical defense applications, and catalytic materials for the mineralization of chemical agents related to demilitarization applications.

| Material | Function |

|---|---|

| 3X Catalyst | Catalyst capable of destroying heteroatom containing chemical agents without loss of reactivity. Catalyst suited for both stockpile and non-stockpile demilitarization applications, and chemical defense applications. |

| No-NOx Catalyst | Catalyst capable of destroying nitrogen-containing compounds with minimal formation of NOx. Catalyst suited for process requiring filtration of nitrogen-containing compounds, such as blood gases, and energetic materials. |

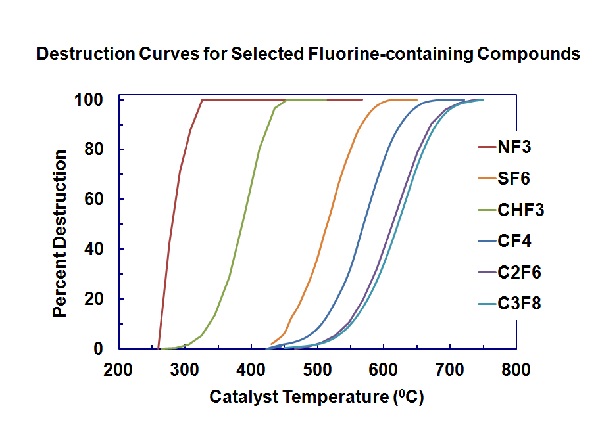

| Perfluorocarbon CatalystPFC-200 | Catalyst capable of destroying perfluorocarbons and hydrofluorocarbons such as sulfur hexafluoride (SF6), trifluoromethane (CHF3), carbon tetrafluoromethane (CF4, R-14) octafluoropropane (C3F8) perfluorocyclobutane (C4F8), nitrogen trifluoride (NF3), with minimal formation of NOx. Catalyst is suited for application in abatement of semiconductor waste gasses and metals smelting gasses. |

The graph to the left displays the destruction curves for various fluorine-containing compounds vs catalyst temperature for PFC-200. The compounds are commonly used in many industries, including semiconductor manufacturing. The key advantage for the PFC-200 is that the catalyst framework material is much more tolerant of hydrofluoric acid than conventional catalysts. So not only does the PFC-200 function at significantly lower temperatures, it has an expected lifetime that is far superior to any other conventional catalyst.

These advances are the direct result of Guild Associates' ability to characterize materials and draw correlation between the physical properties of materials and their performance in a working environment.

Guild Associates is uniquely equipped to develop, evaluate and manufacture materials for user specified applications, such as chemical defense applications. Our development laboratory is equipped with state-of-the-art materials characterization instruments which include X-ray photoelectron spectroscopy (XPS), N2 BET and chemisorption capabilities.

Guild Associates' evaluation laboratory has the capabilities to evaluate materials ranging from adsorbents employed by single-pass and regenerable filters to catalysts used for the destruction of chemical agents, and our manufacturing capabilities permits manufacturing materials from pilot to production scale. Read more about our laboratory capabilities here.

Guild Associates has prior experience building abatement systems and thus is well acquainted with the issues faced by systems manufacturers, consequently we have the knowledge to custom design a reductive catalyst to operate within the parameters of your system. Guild Associates also has partnerships with abatement system manufacturers in various markets that utilize our catalysts, so Guild Associates can connect you with an abatement manufacturer that knows your market well. Whether you are an abatement equipment manufacturer or an end user, share your application with us so we can put our experience to work for you.

Guild Associates engineers and scientists are recognized experts in the field of selective reduction catalysts, and published in peer-reviewed journals and trade magazines and make presentations at industry trade shows. Listed below is a sample of the recent publications, patents and industry presentations.

| 2011 | Sobolevskiy, A.; Rossin, J.A. and Knapke, M.J.; High Temperature Catalytic Process to Reduce Emissions of Carbon Monoxide . U.S. #8,071,062 (2011). |

| 2011 | Sobolevskiy, A.; Rossin, J.A. and Knapke, M.J.; Selective Catalytic Reduction System and Process for Treating NOx Emissions Using a Zinc or Titanium Promoted Palladium-Zirconium Catalyst. U.S. #7,998,940 (2011). |

| 2011 | Sobolevskiy, A.; Rossin, J.A. and Knapke, M.J.; Process for Activation of a Palladium Catalyst System. U.S. #7,989,385 (2011). |

| 2011 | Sobolevskiy, A.; Rossin, J.A. and Knapke, M.J.; Selective Catalytic Reduction System and Process for Treating NOx Emissions Using Palladium and Rhodium or Ruthenium Catalyst. U.S. #7,976,805 (2011). |

| 2010 | Sobolevskiy, A. and Rossin, J.A.; Selective Catalytic Reduction System and Process Using a Pre-sulfated Zirconia Binder. U.S. #7,744,840 (2010). |

| 2010 | Sobolevskiy, A.; Rossin, J.A. and Knapke, M.J.; Catalytic Process for Control of NOx Emissions Using Hydrogen. U.S. #7,718,153 (2010). |

| 2010 | Sobolevskiy, A.; Rossin, J.A. and Knapke, M.J.; High temperature catalyst and process for selective catalytic reduction of NOx in exhaust gases of fossil fuel combustion. U.S. #7,695,703 (2010). |

| 2008 | Sobolevskiy, A. and Rossin, J.A.; Apparatus and Method for Catalytic Treatment of Exhaust Gases. U.S. Patent 7,390,471 (2008). |

| 2004 | Rossin, J.A.; Catalyst Composition and Method of Controlling PFC and HFC Emissions. U.S. Patent #6,676,913 (2004). |

| 2002 | Rossin, J.A.; Catalytic Processes for the Reduction of Perfluorinated Compounds and Hydrofluorocarbons. U.S. Patent #6,673,326 (2004). |

| 2002 | Rossin, J.A. and Maurer, S. M., Catalytic Process for the Decomposition of Perfluoroalkanes. U.S. Patent #6,426,443 (2002). |

| 2001 | Rossin, J.A. and Rosenberg, H.S.; "Dual Function Catalyst Promises High NOx Removal with Zero NH3 slip for Gas Turbine Applications," Power Eng., (Sept. 2001) 76. |

| 2001 | Brown, R.S., Rossin, J.A. and Aitchison, K.; "Catalytic Technology for PFC Emissions Control," Solid State Technology, (July 2001) 189. |

| 2001 | Brown, R.S., Rossin, J.A. and Thomas, C.J.; "Catalytic Process for Control of PFC Emissions," Semiconductor Int., (June, 2001) 209. |